Linkam’s MFS (Modular Force Stage) is a modular system designed to characterise the mechanical properties of samples with temperature and environmental control modules. It can be used to test tension, compression and multi-point bending of various materials, such as polymers, metals, ceramics, biomaterials and nanomaterials. A wide range of analytical techniques are compatible with the stage such as optical microscopy, X-ray, Raman and FTIR to visualise the structural changes of the samples during mechanical testing.

This article investigates the wide range of mechanical testing that can be performed using the MFS; this includes tensile strain testing, compression testing, fracture testing, tensile cycling, three-point bending, adhesion testing and creep testing. This is made possible by exploiting the modularity of Linkam’s MFS with interchangeable heaters and grips that can accommodate an extensive range of temperatures, (from <–195°C up to 600°C), and sample types. The Linkam MFS allows researchers and engineers to explore and enhance how materials behave and last for different applications across a wide range of temperatures and sample types.

Tensile Strain Testing

Tensile strain testing is a useful technique to evaluate the mechanical behaviour of materials under tension. It can provide various types of data, such as:

The stress-strain curve, which shows the relationship between the applied stress and the resulting strain on the sample. The stress-strain curve can reveal important information about the elastic and plastic deformation, the yield point, the ultimate tensile strength, the fracture point, and the ductility of the material.

Young’s modulus is a measure of the stiffness or elasticity of the material, and is calculated as the slope of the linear portion of the stress-strain curve. Young’s modulus indicates how much force is required to stretch or compress the material by a certain amount.

Poisson’s ratio is a measure of how much the material contracts or expands in the direction perpendicular to the applied force. It is calculated as the negative ratio of the lateral strain to the axial strain. Poisson’s ratio indicates how much volume change occurs in the material when it is deformed.

Compression Testing

Compression testing is a method of measuring the mechanical properties of materials under compression. It involves applying a controlled force to a sample and recording the change in length and the stress-strain curve. Compression testing can be used for various types of materials, such as metals, ceramics, polymers, composites, concrete and wood.

Compression testing can provide various types of data, such as the compressive strength, which is the maximum stress that the material can withstand before failure. The compressive strength indicates how resistant the material is to crushing or buckling.

Fracture testing

Fracture testing is a method of evaluating the resistance of materials to crack initiation and propagation under various loading conditions. It can provide information about the fracture toughness, fracture mechanics, fracture modes and fracture criteria of materials. A mechanical force stage (such as the MFS) can be used to apply controlled forces and displacements to a specimen and measure the resulting deformation and fracture behaviour. The MFS can be used for fracture testing of various types of materials, such as metals, ceramics, polymers, composites and biomaterials.

Tensile Cycling

Tensile cycling and hysteresis are related concepts in the study of the mechanical properties of materials. Tensile cycling is a method of applying repeated tensile forces to a material and measuring the resulting stress and strain. Hysteresis is the phenomenon of the stress-strain curve being different for loading and unloading cycles, indicating that some energy is dissipated in the material due to internal friction.

Tensile cycling and hysteresis can reveal important information about a material’s behaviour under cyclic loading, such as cyclic hardening or softening, fatigue limit, fatigue strength, fatigue life, fracture toughness, crack growth rate, energy dissipation, stiffness and damping. Tensile cycling and hysteresis can also be affected by various factors, such as temperature, strain rate, strain amplitude, initial state, microstructure and stacking fault energy of the material.

Three-point bending

A three-point bending test is a method of measuring the flexural properties of materials under bending. It involves placing a sample with a rectangular cross-section against two parallel supports and applying a force at the middle of the sample.

A three-point bending test using a mechanical force stage (such as Linkam’s MFS) can provide various types of data, such as the flexural stress, which is the maximum stress in the outer fibers at the midpoint of the sample. It is calculated as the ratio of the applied force to the cross-sectional area of the sample.

Adhesion Testing

Adhesion testing is a method of measuring the bond strength between two materials. It can provide information about the quality, durability and performance of the bonding agent. Adhesion testing can also reveal the mechanisms of failure, such as cohesive failure, adhesive failure, interfacial failure or mixed failure. One example of adhesion testing is the ‘pull-off test’ which measures the force required to separate two objects bonded together.

Indentation testing

Indentation testing is a method of measuring the hardness, elastic modulus and other mechanical properties of materials by applying a small load to a sharp indenter and measuring the resulting indentation depth or area. Indentation testing can be used for various types of materials, such as metals, ceramics, polymers, composites and biomaterials.

Creep Testing

Creep testing is a method of measuring the deformation of materials under constant stress and elevated temperature over a long period of time. Creep testing can provide information about the creep rate, creep strain, creep life and creep rupture of materials. It can also reveal the mechanisms of creep, such as dislocation glide, climb, diffusion and grain boundary sliding.

Summary

In this article we have provided an overview of the Linkam MFS and its applications in seven types of mechanical testing, namely tensile strain testing, compression testing, fracture testing, tensile cycling, three-point bending, adhesion testing and creep testing. We have explained the principles, methods and data analysis of each type of testing which can be undertaken with the MFS, and have highlighted the benefits of microscopy measurements, such as observing the microstructure, morphology, phase transitions and crack propagation of the samples during mechanical testing. We have also demonstrated the modularity of the MFS, which allows the use of interchangeable heaters and grips that can accommodate a wide range of sample types and temperatures from <‑195°C up to 600°C.

The Linkam MFS is a versatile and powerful system that can perform various types of mechanical testing on different materials with temperature and environmental control modules. It can provide valuable information about the mechanical properties, deformation and fracture behaviour of materials under different loading conditions and temperatures. The MFS is a valuable tool in enabling researchers and engineers to understand and improve the performance and reliability of materials for various applications, and can be combined with different microscopy techniques to visualise the structural changes of the samples during mechanical testing.

Sign up to Linkam Newsletter

References

Huda, Z. (2022). Mechanical Testing and Properties of Materials. In: Mechanical Behaviour of Materials. Mechanical Engineering Series. Springer, Cham.

DOI: 10.1007/978-3-030-84927-6_3

Rahman, R. and Putra, S. F. Z. S. (2019). Tensile properties of natural and synthetic fibre-reinforced polymer composites, In: Woodhead Publishing Series in Composites Science and Engineering, Woodhead Publishing.

DOI: 10.1016/B978-0-08-102292-4.00005-9

Swallowe, G.M. (1999). Tensile and Compressive Testing. In: Mechanical Properties and Testing of Polymers. Polymer Science and Technology Series, vol 3., Springer.

DOI: 10.1007/978-94-015-9231-4_52

International Organization for Standardization. (2019), Plastics — Determination of tensile properties (ISO 527-1:2019(E)).

https://www.iso.org/standard/75824.html

Wen, K., Ma, H., Zhang, J., Cheng, S., Wang, X., Hui, Y., Li, X., Xu, P., Shao, J. and Chen, X.. Electrostatic incitation on fibre surface for enhancing mechanical properties of fibre-reinforced composite, Compos. Sci. and Technol., 228, (2022), 109627.

DOI: 10.1016/j.compscitech.2022.109627

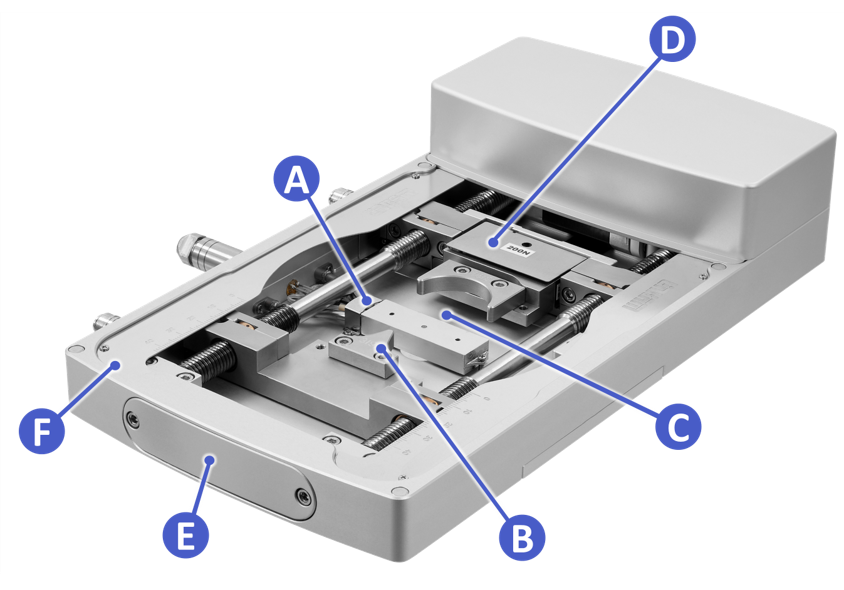

MFS Module Options

MFS stage with labelled modules