The introduction of friendly bacteria into low-fat ice cream is a breakthrough in the search for healthy alternative comfort foods

A research group in Italy is making breakthroughs in research into improving the ability to add good bacteria, known as probiotics, into low-fat ice cream. Probiotics have been promoted for their role in maintaining or improving digestive health, and consumer awareness of these possible health benefits has led to a huge increase in demand for probiotic-enriched food and beverages, in particular in dairy products. One difficult step has been introducing these probiotics into low-fat and healthy foods. Here, we go into more details about how the research group of the University of Udine (Italy) have achieved this.

Probiotics are live microorganisms, mainly bacteria, which are generally considered to provide beneficial effects to the human gastrointestinal system by adding “friendly” bacteria to the gut flora - some common probiotics and their purported properties are listed in the figure below. A sufficient amount of live probiotic bacteria needs to be delivered to the intestine for these friendly bacteria to have an impact. Probiotic bacteria are susceptible to damage from the food processing and storage, as well as from the transit throughout the gastrointestinal tract.

Four types of probiotic bacteria, and some of their health-boosting properties

Significant research efforts are being put into designing probiotic delivery systems able to protect the probiotics against the adverse conditions they face during food production, handling and consumption. One such delivery system is attracting considerable attention in the research community: Saturated monoglyceride structured emulsions (MSEs), which are emulsions consisting of oil and water phases stabilised by saturated monoglyceride. In this case, probiotics have been added to the water phase of skimmed milk.

The group from the University of Udine in Italy investigated the potential of MSEs as delivery systems of probiotics in ice cream. Firstly, they investigated the microbial viability in the emulsions during storage at 4 °C. They found the inclusion of a probiotic Lactobacillus rhamnosus strain in MSEs resulted in a high cell viability during storage at 4°C for up to 2 months [1].

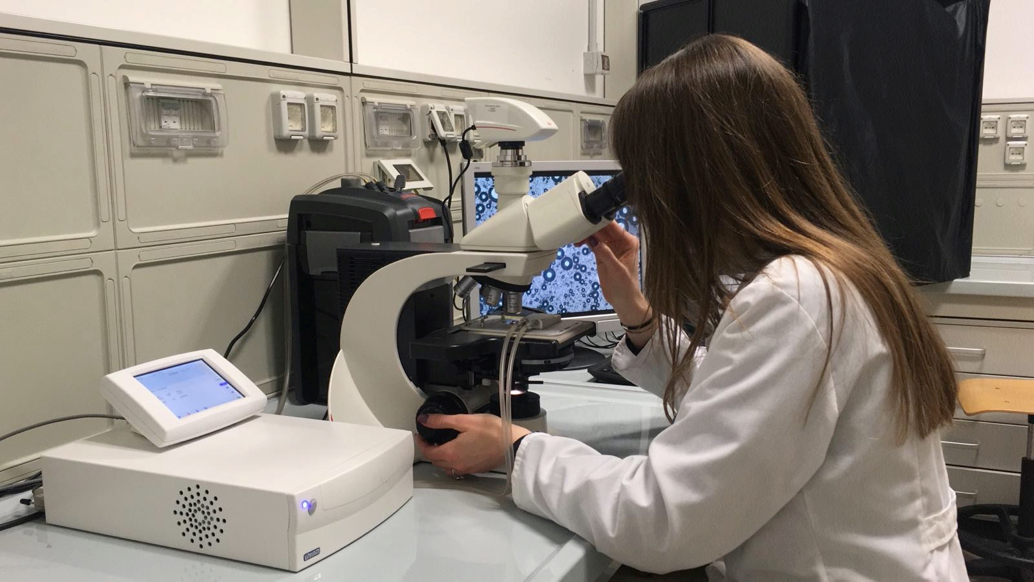

Students look at structured emulsions under the microscope using various Linkam stages in the lab at the University of Udine

The research team that developed the study was composed of researchers belonging to the Department of Agricultural, Food, Animal and Environmental Sciences of the University of Udine (Italy), including Marinela Marino and Sonia Calligaris. Commenting on the research: “In our research group food technologists and food microbiologists merge their expertise to obtain functional foods containing probiotics at the microbial load considered able to confer beneficial effects to the host's health (at least 106–107 CFU/g). In this study we focused our attention on ice-cream that is a particularly challenging product. In fact, both the freezing process and the storage at very low temperatures are known to damage the cell structures leading to a reduction of microbial viability”.

In their breakthrough paper published in LWT – Food Science and Technology [2], the group used a temperature-controlled stage Linkam CSS450 to investigate the microstructure of ice-cream containing MSE delivering probiotics. The images were acquired by placing the ice cream between the parallel plates of the temperature controlled stage, cooled at -7°C. This is facilitated by the precise heating and cooling capabilities of the CSS, as well as its transparent quartz windows on the shear plates enabling optical observation.

The authors were able to observe the distribution of air bubbles into ice-cream made from different formulations with probiotics dispersed by MSEs. They were categorised into three groups as those made with sunflower oil (Oil-MSE), Anhydrous Milk Fat (AMF-MSE), and a control batch formulated with milk fat without MSEs. Air cells in each image were subdivided into three classes, depending on the maximum length of the longest line joining two points of the cell's outline and passing through the centroid (average size): class 1 consisted of air cells with 0–20 μm size, class 2 consisted of air cells with 20–40 μm size, class 3 consisted of air cells with more than 40 μm size. The percentage ratio between the number of air cells belonging to each class and the total number of air cells in the image was calculated.

Meltdown dynamics of ice creams formulated with MSEs compared to the control sample

Oil-MSE ice cream exhibited the lowest number of air cells that were uniformly distributed. On the other hand, AMF-MSE ice cream displayed the highest number of air cells, but they were non-uniformly distributed and closely packed leading to a structure similar to that of a foam. Finally, the control sample showed air bubbles and distribution size so that comparisons could be made between the ice cream prepared with MSE containing oil and that containing anhydrous milk fat. The researchers concluded that the presence of crystalline monoglycerides in oil-MSE containing samples probably allowed partial fat coalescence during whipping and freezing steps, leading to air bubble stabilization which resulted in higher overrun (the amount of ice cream successfully aerated).

The meltdown stability of ice cream is another quality parameter that is affected by the lipid phase structure. The results of this test are shown in the figure above. In this study, the control and the Oil-MSE ice creams showed similar meltdown profiles, whereas the sample containing AMF-MSE had the lowest meltdown resistance. Based on observations of optical microscopic images, it is likely that the high overrun value together with the very close distribution of air cells may have increased the melting rate of AMF-MSE ice cream. The images from the optical microscope can be found in the full article here.

The oil-MSE demonstrated the ability to create a melt-resistant fat network structure in ice cream when milk fat was replaced with sunflower oil. It was concluded that the monoglyceride crystalline structures formed in the MSE played both a probiotic protective and structuring role. The use of MSE containing sunflower oil makes it possible not only to successfully protect probiotic bacteria, but also to formulate a low saturated fat ice cream – which could deliver added appeal for health-conscious consumers.

Please contact Dr Marilena Marino for more information on this research.

For more information on the CSS450, please contact Linkam

References

[1] Marino, M., Innocente, N., Calligaris, S., Maifreni, M., Marangone, A., & Nicoli, M. C. (2017). Viability of probiotic Lactobacillus rhamnosus in structured emulsions containing saturated monoglycerides. Journal of Functional Foods, 35, 51–59.

[2] Calligaris, S, Marino, M, Maifreni, M, Innocente, N (2018), Potential application of monoglyceride structured emulsions as delivery systems of probiotic bacteria in reduced saturated fat ice cream, LWT – Food Science & Technology, 96, 329-334.

Related Content: